Dyeing fabric is one of the oldest industries in the world, with the very earliest dyeing instruments being dated at 400,000 years old. Throughout the majority of human history, fabrics have been dyed by using pigments derived from rocks or soils that are gathered and ground up. In some instances, the pigments are then roasted over the fire to cause the colors to deepen. For millennia, these natural pigments﹘which span a wide range of colors﹘were the foundation of all our dyed materials until the mid-19th Century, when a British chemist by the name of William Perkins accidentally discovered the first synthetic pigment while trying to create quinine for the treatment of malaria. Since that time, the commercial dyeing industry has largely moved away from using natural pigments.

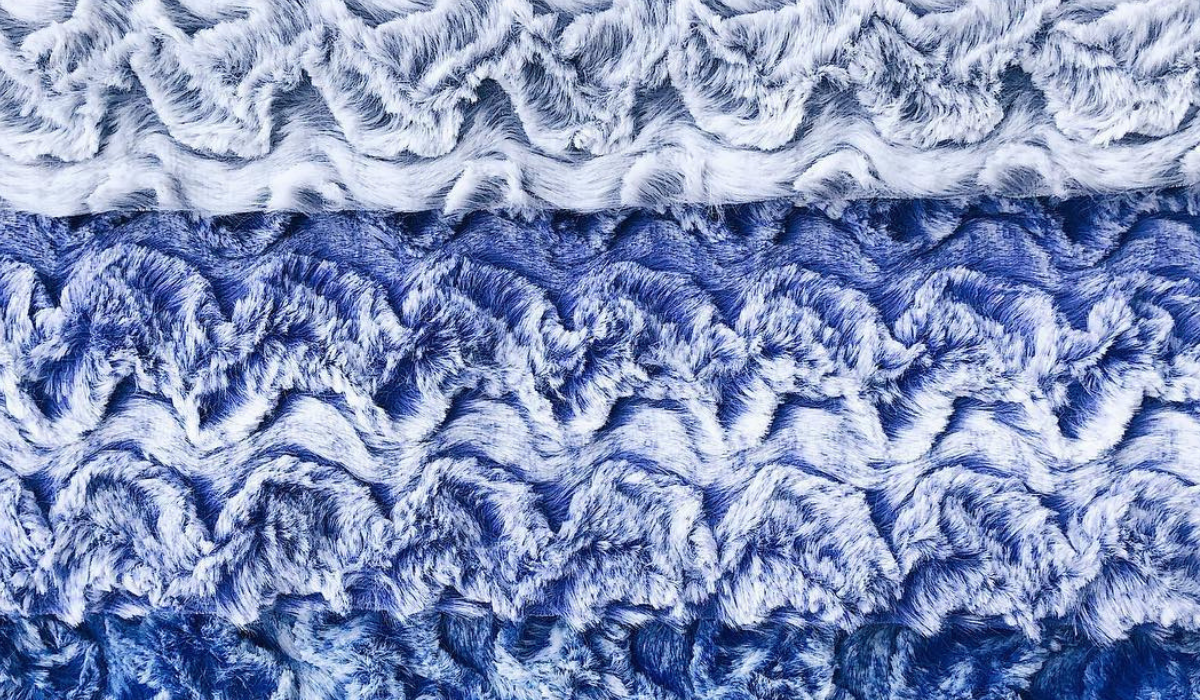

Dyeing Minky Blanket Fabric

There are numerous techniques used in the dyeing process, and the time that these dyes are added can vary as well. Indeed, your favorite Minky blankets could have had their dyes applied before their polyester fibers were even created (a process called ‘dope dyeing’ wherein the synthetic pigments are added to the polymer itself). Other stages of dyeing include:

Fiber Dyeing

Yarn Dyeing

Piece Dyeing

Garment Dyeing

As you can see, each stage in the life of a Minky blanket can have color added to it, from the dope wherein the fibers are extracted, the yarn created by the fibers, the fabrics created from the yarn, and the garment created by sewing the fabrics together. By systematically adding color at any one or more of these stages, the Minky blanket fabric we are famous for using is made beautiful by its stunning new sheen.

How Dyeing Works

Historically, dye has been added to fabrics in one of two ways. The first, a technique called the exhaust method, centers on the liquid colored by the pigment and how it’s used in relation to the fabric. The exhaust method submerges the fabric in this liquid and either churns the water around the clothes or moves the clothes within the water. These methods are called ‘liquor circulating’ and ‘material circulating,’ respectively. The second technique is called the continuous method, where color is affixed by steaming the color on.

Ultimately, using either of these two methods, the pigment﹘which is insoluble in water﹘is chemically bonded to the fabric. Ideally, the bond should be strong enough to hold onto the fabric without eventually letting the colors fade or run. The likelihood of this happening is measured against the dye’s colorfastness rating. The higher the color fastness, the better chance that Minky baby blanket will hold up to numerous washings.

The Pros and Cons of Dyeing

While these two techniques, the exhaust and continuous method, are used most often in the commercial dyeing industry, a few intrepid companies have been spending more time, money, and effort in research and development to come up with newer ways to dye materials like Minky blankets. As it stands, the pigment industry is worth nearly $20 billion a year with projections outpacing that year-over-year. However, nearly $1 billion is lost each year due to inefficiencies in the dyeing process.

These companies are exploring new technologies, like deriving pigments from microorganisms or proteins, as well as developing new methods of pretreating materials before they are dyed, thus saving money, water, and consequently, the environment.